Understanding the Importance of a Good Concrete Sub-Base

Building a robust concrete base begins from the ground up, and that starts with a good sub-base. A question we are frequently asked by our customers is “What should I use as Hardcore for a Concrete Base?”. Choosing the right hardcore for a concrete base will play a part in detirmining how strong that base is, and should not be overlooked.

What is a Concrete Sub-base?

A sub-base is a layer of aggregate material, such as hardcore aggregate, gravel, crushed stone, or sand, placed on the sub-grade (the ground soil) before the concrete base is installed. It is a critical part of any paving or concreting project as it provides support and stability to the concrete base.

The sub-base is the layer of material directly underneath your reinforced concrete base, and its purpose is to distribute the load evenly, preventing your concrete from sinking, cracking, or heaving. Much like constructing a house on an unstable foundation, a concrete base without a solid sub-base will not perform optimally.

The two main functions of a sub-base are:

- Load Distribution: It spreads out the load of the concrete base across a larger area, reducing pressure on any single spot and helping to prevent the concrete from sinking or cracking.

- Drainage: It aids in water drainage, preventing water from pooling under the concrete and causing damage.

Choosing the Right Material for Your Concrete Sub-base

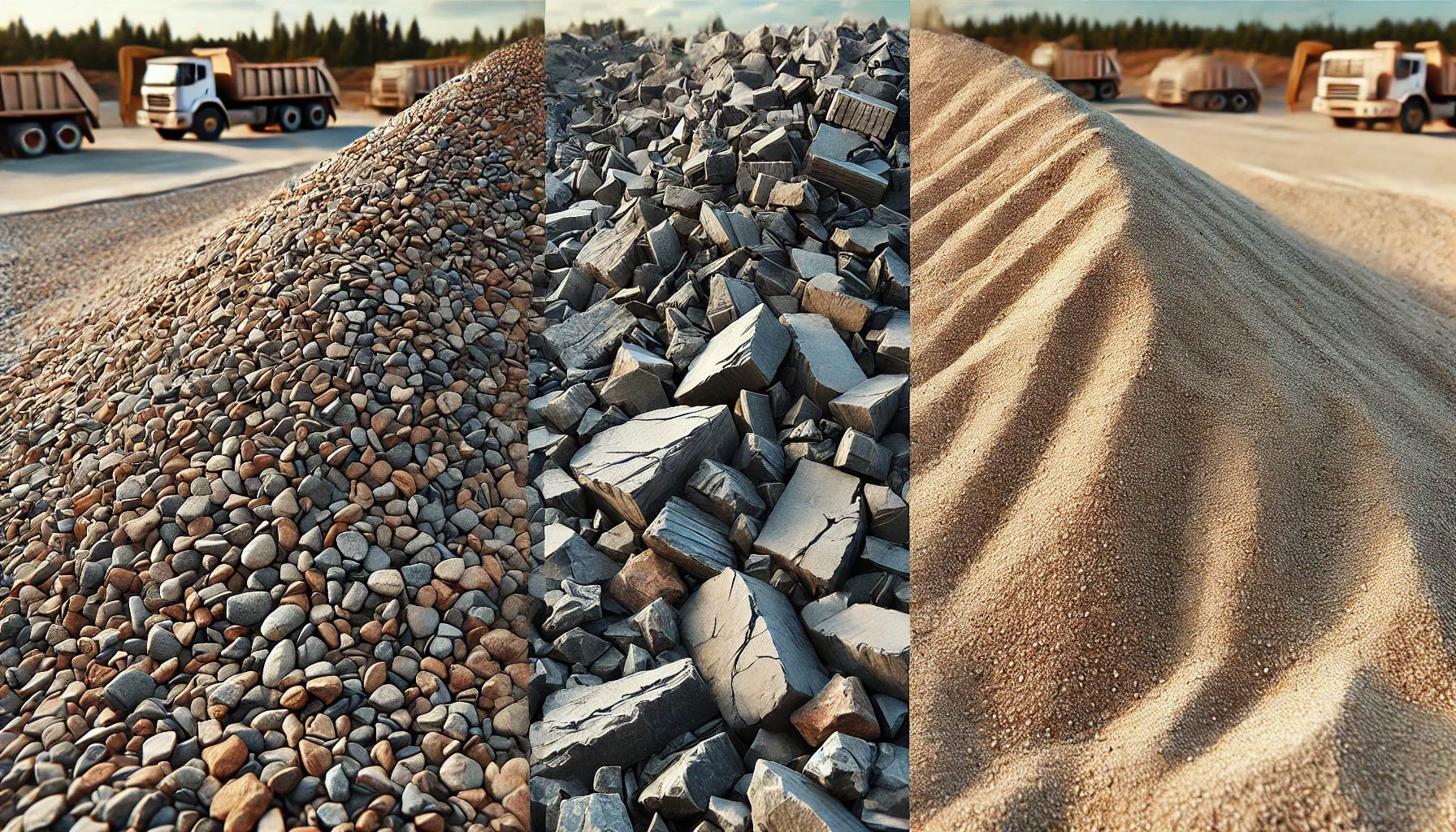

Choosing the right material for your sub-base is crucial for the overall performance of your concrete base. The most commonly used materials for a sub-base include:

- Gravel: Popular for its excellent drainage properties and ability to distribute the load evenly. Gravel also resists frost heaving in cold climates.

- Crushed Stone: Offers high stability and strength. It packs down well and provides a solid foundation for concrete. This is the recommended sub-base material for a garage base.

- Sand: Can be used in some scenarios, particularly for smaller jobs or in areas with a high water table.

The choice of sub-base material depends on your project’s nature, local climate, and sub-grade soil condition.

Preparing the Area for a Concrete Base

Before laying your concrete base, proper preparation is crucial. Here’s what you need to do:

- Clearing the Area: Remove debris, vegetation, or obstructions. Organic material can decompose and compromise your concrete base.

- Leveling the Ground: Ensure the ground is flat and even using a spirit level to prevent issues like cracking or shifting.

- Digging Out the Area: Excavate the space to a depth of around 100-150mm. The depth impacts the strength of the base.

- Installing the Sub-base: Lay and compact the hardcore base—usually compacted MOT Type 1 hardcore—to a thickness of 100mm to 150mm.

- Adding a Membrane: Consider adding a damp-proof membrane between the sub-base and the concrete to prevent moisture seepage and control expansion and contraction.

Compacting the Sub-base for Optimal Stability

Proper compaction of the sub-base is essential for a stable concrete base. Use a mechanical vibrating plate (also known as a compactor or Whacker Plate) to compact loose materials like soil, sand, or gravel. This tool ensures:

- Compaction: Creates a solid and sturdy foundation.

- Leveling: Reduces the risk of an uneven base.

- Water Drainage: Improves drainage and reduces the likelihood of water accumulation.

Dealing with Poor Soil Conditions

Poor soil conditions can affect the quality of your concrete base. Here’s how to address common soil problems:

- Loose or Sandy Soil: Opt for soil compaction or add filler materials like gravel.

- Expansive Clay Soil: Use concrete designs that withstand movement or add lime to mitigate expansion.

- Organic Soil: Excavate and replace with more suitable fill material.

Additionally, manage high water tables by installing a good drainage system and grading the surrounding land to direct excess rainwater away from the base area.

For concrete delivery and supply services across Surrey, Berkshire, and Middlesex, contact 365 Concrete. We provide high-quality concrete and efficient delivery solutions for your projects.

Call us today at 0208 751 0101 for reliable service and assistance with all your concrete needs.